The Case for RDF: Benefits and Drawbacks for Plastics Recycling

by RDF'er

Posted on 12-03-2023 03:14 PM

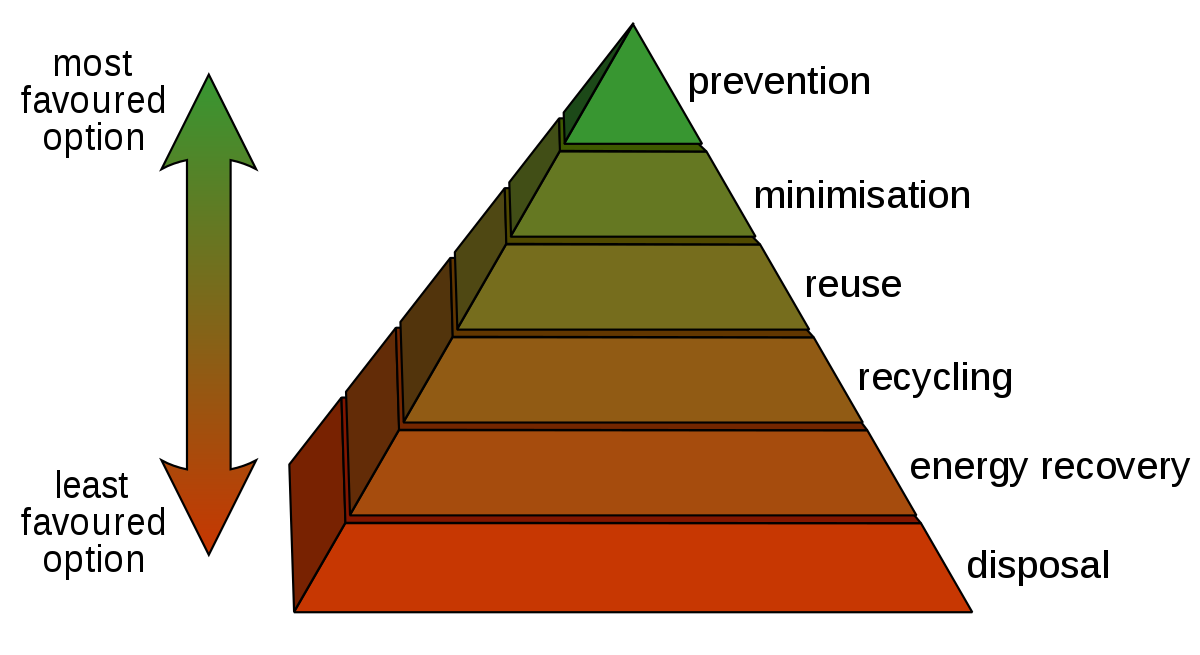

As society becomes increasingly aware of the environmental impact of waste, the waste hierarchy has become a useful tool for managing waste sustainably. The waste hierarchy lists the various methods for processing municipal and commercial waste in order of preference. At the top of the hierarchy is prevention, followed by reuse, recycling, energy recovery, and lastly, disposal. One method of waste treatment that falls under the category of energy recovery is Refuse Derived Fuel (RDF).

RDF is a useful fuel for incinerators, but a lot of the heat it produces during combustion comes from the plastic in it.

Now few would dispute that it is essential to recycle plastic far more than in the past to avoid it entering the environment, and the recycled plastic resin has a far higher monetary value than the plastic in RDF. Many people hope that plastic recycling will one day reach the same high percentage rates as for metal cans which can be as high as 90% or more.

The result of such a high recycling rate is that metal can production require very little additional metal to be mined each year, and the same is hoped for with plastic in the years to come.

If most plastic is recycled it will have a real value. When that happens, market forces will ensure that plastic does not enter the environment and food chains. The market will do that far more effectively than any regulation, so apart from any other reason for recycling plastics it should be the chosen option.

Read on and after explaining the background to this subject for our non-expert audience we will discuss the implications of a much higher plastic recycling rate for waste management and energy recovery in the future.

What is Refuse Derived Fuel (RDF)?

Refuse Derived Fuel (RDF) is a fuel that is produced by shredding and drying municipal solid waste (MSW) and commercial waste. The waste is sorted and processed to remove recyclable materials, such as plastics, metals, and glass, before being shredded into smaller pieces. The resulting RDF can be used as a fuel in waste-to-energy facilities, cement kilns, and industrial boilers. RDF is a form of energy recovery because it converts waste into a useful resource, reducing the amount of waste sent to landfill.

RDF in the Waste Hierarchy

RDF falls under the category of energy recovery in the waste hierarchy. Energy recovery is the process of generating energy from waste that cannot be recycled. It is considered a preferable method of waste treatment to disposal because it reduces the amount of waste sent to landfill and generates energy in the process.

However, energy recovery is still considered less preferable than recycling because it does not reduce the need for raw materials, and it can potentially compete with recycling for waste streams. Recycling is the preferred method of waste treatment because it conserves resources and reduces the environmental impact of waste.

Other Methods of Waste Treatment in the Waste Hierarchy

Image: The Waste Hierarchy Pyramid

Drstuey at the English-language WikipediaPrevention:

This is the most desirable method of waste treatment because it involves reducing the amount of waste generated in the first place. Prevention can be achieved through measures such as reducing packaging and encouraging sustainable consumption.

Reuse:

Reuse involves finding new uses for products or materials that would otherwise be discarded. It is a preferred method of waste treatment because it extends the lifespan of products and reduces the need for new ones.

Recycling:

Recycling is the process of converting waste materials into new products. It is a preferred method of waste treatment because it conserves resources and reduces the environmental impact of waste.

Energy Recovery:

Energy recovery is the process of generating energy from waste that cannot be recycled. It is considered a preferable method of waste treatment to disposal because it reduces the amount of waste sent to landfill and generates energy in the process.

Disposal:

Disposal is the last resort in the waste hierarchy and involves sending waste to landfill or incineration without energy recovery. Disposal is the least preferable method of waste treatment because it does not reduce the environmental impact of waste and does not generate useful resources.

Comparison of RDF with Other Methods in the Waste Hierarchy

Compared to other methods of waste treatment, RDF falls just below the middle of the waste hierarchy. It is a more preferable method than disposal because it generates energy and reduces the amount of waste sent to landfill. However, it is less preferable than recycling and prevention because it does not conserve resources or reduce the environmental impact of waste.

Recycling is considered the preferred method of waste treatment because it conserves resources and reduces the environmental impact of waste. RDF competes with recycling for waste streams, and it does not reduce the need for raw materials. However, RDF can be a useful method of waste treatment for waste that cannot be recycled, such as non-recyclable plastic materials.

Plastic as a Key Component of RDF: Implications for Waste Management and Energy Recovery

As we indicated earlier, refuse-derived fuel, or RDF, is a type of fuel produced from the processing of municipal solid waste (MSW). RDF is a blend of different waste streams, such as paper, cardboard, plastics, textiles, and wood, that have been sorted, shredded, and dried to create a homogeneous fuel. One of the key characteristics of RDF is its high calorific value, which makes it an attractive fuel source for energy recovery.

However, a large part of the calorific value of RDF comes from the plastic content in it.

In fact, according to a report by the European Union, the plastic content of RDF can account for up to 50% of its energy content. This is because plastics have a high carbon content and produce a lot of energy when burned.

This raises the question of whether it is better to recycle plastics or use them as fuel in RDF. Recycling plastics is generally seen as the preferred option, as it reduces the amount of waste that ends up in landfills and conserves natural resources. However, if plastic is removed from the waste stream before RDF production, it will have a significant impact on the calorific value and the market for RDF.

To Recycle or to Burn: The Trade-offs of Plastics in RDF Production.

If plastic is taken out of the waste stream for recycling, the remaining waste will have a lower calorific value and may not be as attractive as a fuel source. This could reduce the demand for RDF, potentially affecting the market for RDF and the economics of waste management.

On the other hand, if plastic is not removed from the waste stream, it will continue to contribute to the high calorific value of RDF, but it will also mean that more plastic is being used as fuel rather than being recycled. Hence, more non-renewable oil will have to be used, raising carbon dioxide emissions when burnt and worsening the climate change effect.

Until now, removing plastic from source-separated food waste before it enters the RDF production process has been a significant challenge. The primary issue has been that most depackaging machines available on the market are size reduction machines. These machines break down the plastic into small fragments, making it impossible to recover in a form suitable for recycling or RDF production. Even the few machines that do keep the plastic in large enough pieces for the output to be baled or pelletized for RDF production have faced the problem of excessive wetness and contamination with organic material. This contamination significantly lowers the calorific value of the plastic, rendering it unsuitable for use in RDF.

New Depackaging Machine Technology Now Makes it Possible to Produce RDF Quality Reject Stream Output Where Previously it was Only Possible to Send it to Landfill

This situation has now changed with the advent of the Twister Depackager and Separator. is revolutionizing the process by efficiently separating plastic from organic material in a way that maintains the integrity of the plastic, allowing it to be baled or pelletized for RDF. What sets the Twister apart is its unique design, which ensures that the rejected plastic is kept dry and free from significant contamination. This greatly enhances its calorific value, making it an excellent feedstock for RDF production. Additionally, the Twister produces a high-quality organic pulp that is ideal for use in anaerobic digestion plants, contributing to a more efficient and sustainable waste management process.

Concluding the Case for RDF: Benefits and Drawbacks for Plastics Recycling

So, is it really best to send plastic to incineration as RDF, or to go to the cost and effort of recycling it, given the complexities of sorting and cleaning plastic before recycling the resin.

There is no easy answer to this dilemma, and it ultimately depends on the priorities of society. If the goal is to minimize waste and conserve natural resources, then recycling plastics should be the preferred option. RDF is lower in the waste heirarchy may be a more attractive option especially during the transition period now in progress.

In conclusion, the plastic content of RDF plays a significant role in its calorific value and attractiveness as a fuel source. While recycling plastics is generally preferred, removing plastic from the waste stream for recycling will impact the economics of RDF and the market for RDF as a fuel.

It is up to society to weigh the benefits and drawbacks of each option and determine the best course of action for waste management and energy recovery.